Description

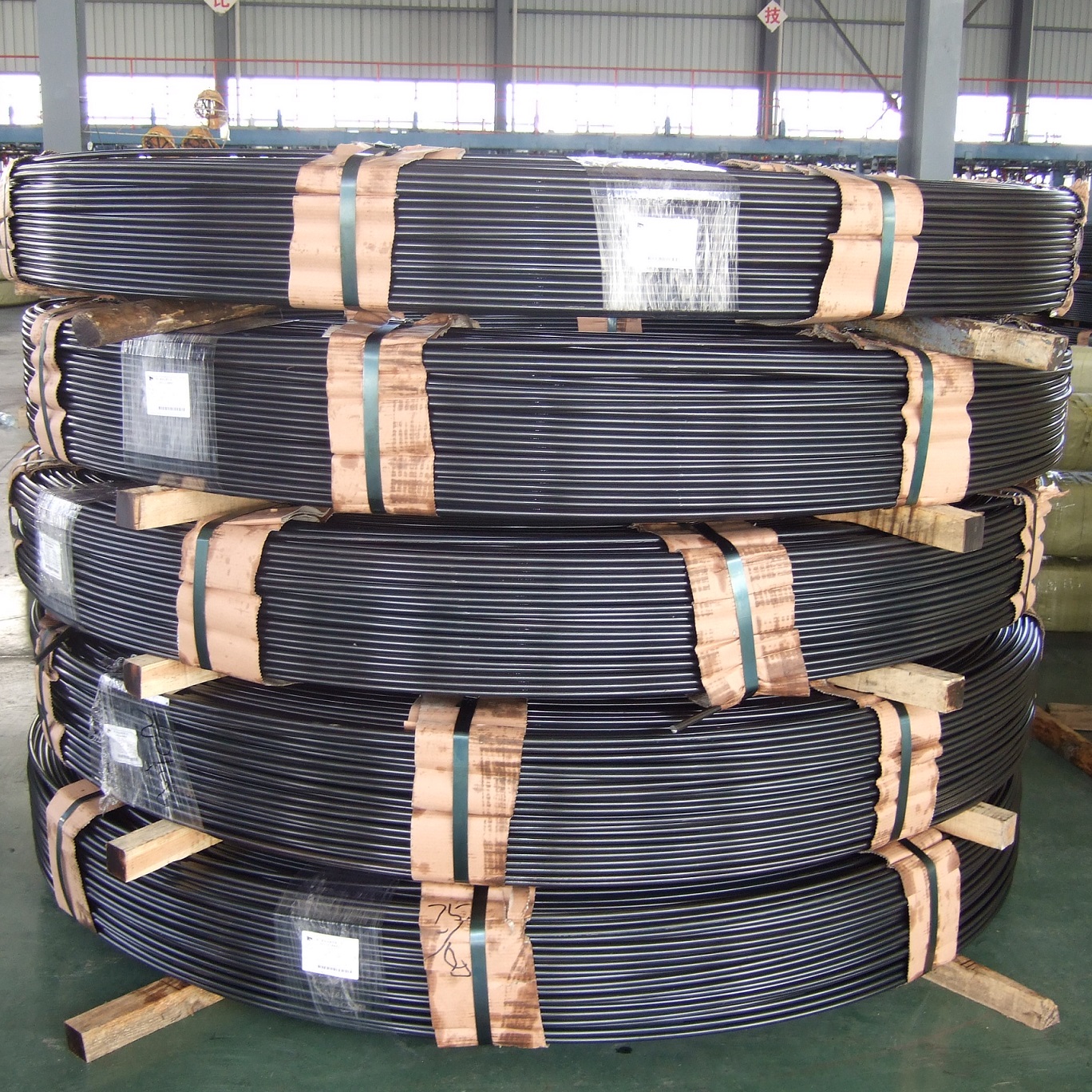

Oil tempered steel wire is widely used for springs that require extremely high resistance to fatigue, heat, and permanent set in fatigue, including the valve springs of the engine, clutch springs, and suspension springs that are considered important security parts of automobiles. Our high-quality oil tempered wire has a large share in both domestic and overseas markets.

Our customers choose oil tempered high carbon steel wire for their custom spring and custom wire form manufacturing projects because it is inexpensive, readily available, and easy to work with.

Details

High Tensile Strength Quality

Some important springs and severely worn springs that work under high stress fatigue performance, such as spring rings, shock absorption springs, brake springs, coil springs for automobiles, locomotives, and tractors, cylinder safety valve springs, etc.

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | |

| EN10270-2 | FD SiCr | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.030 | 0.025 | 0.12 | 0.50-0.80 | |

| EN10270-2 | FD SiCrV | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.020 | 0.020 | 0.10 | 0.50-1.00 | 0.10-0.25 |

8.00-17.00mm

about 1000 kg/coil, OD: about 2.0 meter Max.;

or about 2000 kg/coil, OD: about 2.2 meter MAX.

| Grade | Diameter (mm) | T/S (Mpa) | R/A % |

| SiCr | 8.00-17.00 | 1850-1950 | ≥35 |

| SiCr | 8.00-17.00 | 1950-2050 | ≥35 |

| SiCrV | 8.00-15.00 | 2000-2100 | ≥35 |

Carbon Steel Spring Wire for Static

For statically stressed springs and springs working in the finite life range.

| Standard | Chemical Composition, % by mass | |||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Ni max. | |

| EN10270-2 | FDC | 0.60-0.75 | 0.15-0.35 | 0.50-1.20 | 0.030 | 0.025 | 0.12 | |

| ASTM A229 | 0.55-0.85 | 0.15-0.35 | 0.30-1.20 | 0.040 | 0.050 | |||

| JIS G 3560 | SWO-B | 0.53-0.88 | 0.10-0.35 | 0.30-1.20 | 0.030 | 0.030 | ||

| GB/T 18983 | FDC | 0.60-0.75 | 0.17-0.37 | 0.90-1.20 | 0.030 | 0.030 | 0.25 | 0.35 |

0.50-13.00mm

0.50-0.80mm: 10-15kg per B60 spool

0.90-1.20mm: 15-30kg per Z2 coil

1.30-1.70mm: 400-450kg per wooden spool

1.80-3.00mm: about 300kg/coil

3.10-4.90mm: about 500kg/coil

5.00-13.00mm: about 800 kg/coil or 1200 kg/coil or 2400kg/coil

Silicon-Chromium Spring Wire for Static

For statically stressed springs or springs working in the finite life range, requiring strength at elevated temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | Ni max. | |

| EN10270-2 | FD SiCr | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.030 | 0.025 | 0.12 | 0.50-0.80 | |

| ASTM A401 | 0.51-0.59 | 1.20-1.60 | 0.60-0.80 | 0.035 | 0.040 | 0.60-0.80 | |||

| JIS G 3560 | SWOSC-B | 0.51-0.59 | 1.20-1.60 | 0.50-0.90 | 0.035 | 0.035 | 0.55-0.90 | ||

| GB/T 18983 | FD SiCr | 0.51-0.59 | 1.20-1.60 | 0.50-0.80 | 0.025 | 0.020 | 0.25 | 0.50-0.80 | 0.35 |

0.50-20.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-16.00mm: 1000-2000kg/coil

16.10-20.00mm: 1000-2000kg/coil

Chromium -Vanadium Spring Wire for Static

The round, oil quenched and tempered alloy steel wire FD CrV is used mainly for static torsion loaded springs (tension and compression springs).

| Standard | Chemical Composition, % by mass | |||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | Ni max. | |

| EN10270-2 | FDCrV | 0.62-0.72 | 0.15-0.30 | 0.50-0.90 | 0.030 | 0.025 | 0.12 | 0.40-0.60 | 0.15-0.25 | |

| GB/T 18983 | FD CrV | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.02 | 0.25 | 0.80-1.10 | 0.10-0.20 | 0.35 |

0.50-10.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Silicon-Chromium-Vanadium Spring Wire for Static

For statically stressed springs or springs working in the finite life range, requiring strength at elevated temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | |

| EN10270-2 | FD SiCrV | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.030 | 0.025 | 0.12 | 0.50-1.00 | 0.10-0.25 |

0.50-10.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Carbon Steel Spring Wire for Medium Fatigue

For the manufacture of mechanical springs that can withstand moderate fatigue stresses over somerelatively low number of cycles, such as required for clutch springs.

| Standard | Chemical Composition, % by mass | |||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Ni max. | |

| EN10270-2 | TDC | 0.60-0.75 | 0.15-0.35 | 0.50-1.20 | 0.200 | 0.200 | 0.10 | |

| GB/T 18983 | TDC | 0.60-0.75 | 0.17-0.37 | 0.90-1.20 | 0.030 | 0.030 | 0.25 | 0.35 |

0.50-13.00mm

0.50-0.80mm: 10-15kg per B60 spool

0.90-1.20mm: 15-30kg per Z2 coil

1.30-1.70mm: 400-450kg per wooden spool

1.80-3.00mm: about 300kg/coil

3.10-4.90mm: about 500kg/coil

5.00-13.00mm: about 800 kg/coil or 1200 kg/coil or 2400kg/coil

Silicon- Chromium Spring Wire for Medium Fatigue

For coil springs subjected to moderate dynamic stresses, such as clutch springs or springs requiring similar moderate fatigue resistance as well as high tensile strength and excellent relaxation properties at elevated temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | Ni max. | |

| EN10270-2 | TD SiCr | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.025 | 0.020 | 0.10 | 0.50-0.80 | |

| ASTM A1000 | Grade A | 0.51-0.59 | 1.20-1.60 | 0.50-0.80 | 0.025 | 0.025 | 0.60-0.80 | ||

| GB/T 18983 | FD SiCr | 0.51-0.59 | 1.20-1.60 | 0.50-0.80 | 0.025 | 0.020 | 0.25 | 0.50-0.80 | 0.35 |

0.50-20.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-16.00mm: 1000-2000kg/coil

16.10-20.00mm: 1000-2000kg/coil

Chromium -Vanadium Spring Wire for Medium Fatigue

For the manufacture of mechanicalsprings that can withstand moderate fatigue stresses over somerelatively low number of cycles, such as required for clutch springs.

| Standard | Chemical Composition, % by mass | |||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | Ni max. | |

| EN10270-2 | TD CrV | 0.62-0.72 | 0.15-0.30 | 0.50-0.90 | 0.025 | 0.020 | 0.10 | 0.40-0.60 | 0.15-0.25 | |

| ASTM A231 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.035 | 0.040 | 0.80-1.10 | 0.15 min. | |||

| ASTM A1000 | Grade C | 0.60-0.70 | 0.15-0.30 | 0.50-0.90 | 0.025 | 0.025 | 0.35-0.60 | 0.15-0.25 | ||

| GB/T 18983 | TD CrV | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.02 | 0.25 | 0.80-1.10 | 0.10-0.20 | 0.35 |

0.50-10.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Silicon-Chromium-Vanadium Spring Wire for Medium Fatigue

For coil springs subjected to moderate dynamic stresses, such as clutch springs or springs requiring similar moderate fatigue resistance as well as high tensile strength and excellent relaxation properties at elevated temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | |

| EN10270-2 | TD SiCrV | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.020 | 0.020 | 0.10 | 0.50-1.00 | 0.10-0.25 |

| ASTM A1000 | Grade D | 0.55-0.68 | 1.20-1.65 | 0.50-0.90 | 0.025 | 0.025 | 0.50-0.80 | 0.08-0.25 | |

0.50-10.00mm

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Carbon Valve Spring Quality

For statically stressed springs or springs working in the finite life range, requiring strength at elevated temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Ni max. | V | |

| EN10270-2 | VDC | 0.60-0.75 | 0.15-0.30 | 0.50-1.00 | 0.020 | 0.020 | 0.06 | ||

| ASTM A230 | 0.60-0.75 | 0.15-0.35 | 0.60-0.90 | 0.025 | 0.030 | ||||

| JIS G 3561 | SWO-V | 0.60-0.75 | 0.12-0.32 | 0.60-0.90 | 0.025 | 0.025 | 0.20 | ||

| GB/T 18983 | VDC | 0.60-0.75 | 0.17-0.37 | 0.90-1.20 | 0.030 | 0.030 | 0.25 | 0.35 | |

1.50-2.29mm (Shaved);

2.30-10.00mm (Shaved & Eddy Current Tested)

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Chromium-Vanadium Alloy Valve Spring Quality

Chromium-vanadium are designed for springs that must withstand considerable shock and extreme heat. Valve spring quality chrome vanadium has been eddy current tested to assure the finest possible surface in keeping with automotive industry requirements.

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | |

| EN10270-2 | VD CrV | 0.62-0.72 | 0.15-0.30 | 0.50-0.90 | 0.025 | 0.020 | 0.06 | 0.40-0.60 | 0.15-0.35 |

| ASTM A232 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.020 | 0.035 | 0.80-1.10 | 0.15 min. | ||

| JIS G 3561 | SWOCV-V | 0.45-0.55 | 0.15-0.35 | 0.65-0.95 | 0.025 | 0.025 | 0.20 | 0.80-1.10 | 0.15-0.35 |

| GB/T 18983 | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.020 | 0.25 | 0.80-1.10 | 0.10-0.20 | |

0.50-2.29mm (Shaved);

2.30-10.00mm (Shaved & Eddy Current Tested) ( Wire rod from Bao Steel)

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Silicon-Chromium Alloy Valve Spring Quality

Chromium-vanadium are designed for springs that must withstand considerable shock and extreme heat. Valve spring quality chrome vanadium has been eddy current tested to assure the finest possible surface in keeping with automotive industry requirements.

| Standard | Chemical Composition, % by mass | ||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | |

| EN10270-2 | VD CrV | 0.62-0.72 | 0.15-0.30 | 0.50-0.90 | 0.025 | 0.020 | 0.06 | 0.40-0.60 | 0.15-0.35 |

| ASTM A232 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.020 | 0.035 | 0.80-1.10 | 0.15 min. | ||

| JIS G 3561 | SWOCV-V | 0.45-0.55 | 0.15-0.35 | 0.65-0.95 | 0.025 | 0.025 | 0.20 | 0.80-1.10 | 0.15-0.35 |

| GB/T 18983 | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.020 | 0.25 | 0.80-1.10 | 0.10-0.20 | |

0.50-2.29mm (Shaved);

2.30-10.00mm (Shaved & Eddy Current Tested) ( Wire rod SiCrV from Bao Steel, Saarstahl and POSCO)

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Silicon-Chromium-Vanadium Alloy Valve Spring Quality

Especially suitable for coil springs subjected to high dynamic stresses requiring good fatigue resistance (e.g., valve springs), as well as for springs which require high tensile strength and excellent relaxation properties at moderately elevated working temperatures (up to approx. 250 °C).

| Standard | Chemical Composition, % by mass | |||||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Cr | V | Ni max. | |

| EN10270-2 | VD SiCrV | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.020 | 0.020 | 0.06 | 0.50-1.00 | 0.10-0.25 | |

| ASTM A877 | Grade B | 0.55-0.70 | 1.20-1.65 | 0.50-0.80 | 0.025 | 0.025 | 0.08-0.25 | |||

| GB/T 18983 | VD SiCrV | 0.62-0.70 | 1.20-1.60 | 0.50-0.80 | 0.025 | 0.020 | 0.12 | 0.50-0.80 | 0.10-0.20 | 0.035 |

0.50-2.29mm (Shaved);

2.30-10.00mm (Shaved & Eddy Current Tested) ( Wire rod SiCrV from Bao Steel, Saarstahl and POSCO)

0.50-1.40mm: 20-80kg/coil

1.50-1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-10.00mm: 1000-2000kg/coil

Silicon-Manganese Steel Spring Wire

60Si2Mn (=60SiCr7=SUP7=9260) spring steel is a silicon manganese spring steel which is widely used. Its strength, elasticity and hardenability are slightly higher than 55Si2Mn. In the 60Si2Mn spring steel industry, flat springs bearing heavy loads or coil springs with wire diameter less than 30mm can be manufactured, and it is also suitable for making heat-resistant springs in non-corrosive media with working temperature below 250 ℃, large and important coil springs bearing alternating loads and working under high stress, as well as automobile damping systems.

| Standard | Chemical Composition, % by mass | |||||||

| Grade | C | Si | Mn | P max. | S max. | Cu max. | Ni max. | |

| GB/T 18983 | FD SiMn / TD SiMn | 0.56-0.64 | 1.50-2.00 | 0.70-1.00 | 0.025 | 0.020 | 0.25 | 0.35 |

| JISG 3560 | SWOSM | 0.56-0.64 | 1.50-1.80 | 0.70-1.00 | 0.035 | 0.035 | 0.30 | |

| FDSiMn / TDSiMn in GB/T 18983-2017 | ||||||||

| Size Range (mm) | Tensile Strength (Mpa) | Reduction of Area % | Size Range (mm) | Tensile Strength (Mpa) | Reduction of Area % | |||

| FD | TD | FD | TD | |||||

| 0.80-1.60 | 1850-2100 | 45 | 45 | 5.00-5.60 | 1660-1810 | 35 | 40 | |

| 1.60-2.00 | 1820-2000 | 45 | 45 | 5.60-6.00 | 1650-1800 | 35 | 40 | |

| 2.00-2.50 | 1800-1950 | 45 | 45 | 6.00-6.50 | 1640-1790 | 35 | 40 | |

| 2.50-2.70 | 1780-1930 | 45 | 45 | 6.50-7.00 | 1630-1780 | 35 | 40 | |

| 3.00-3.20 | 1740-1890 | 40 | 45 | 7.00-8.00 | 1620-1770 | 35 | 40 | |

| 3.20-3.50 | 1720-1870 | 40 | 45 | 8.00-9.00 | 1610-1760 | 30 | 35 | |

| 3.50-4.00 | 1710-1860 | 40 | 45 | 9.00-10.00 | 1600-1750 | 30 | 35 | |

| 4.00-4.20 | 1700-1850 | 40 | 45 | 10.00-12.00 | 1580-1730 | 30 | 35 | |

| 4.20-4.50 | 1690-1840 | 40 | 45 | 12.00-14.00 | 1560-1710 | 30 | 35 | |

| 4.50-4.70 | 1680-1830 | 40 | 45 | 14.00-15.00 | 1550-1700 | 30 | 35 | |

| 4.70-5.00 | 1670-1820 | 35 | 45 | |||||

1.7-16.0mm

1.70mm: 50-150kg/coil

1.80-2.20mm: 200-300kg/coil

2.30-5.90mm: 400-600kg/coil

6.00-8.90mm: 500-1000kg/coil

9.00-16.00mm: 1000-2000kg/coil

We'd love to hear from you.

If you have any inquiries or need support regarding Skyrit, please fill out the form on this page or use the email address and phone number provided to contact us directly.